indenter rockwell hardness tester|rockwell hardness test explained : store Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500;

[email protected]; .

Vídeo do TikTok de Squadgamers (@squadgamers21): "Errei fui mlk #meme #neymarjr".som original - Squadgamers.

{plog:ftitle_list}

View All Plows. Winches. Standard Winches. Kolpin Quick-Mount Winches. ATV Winch Mounts. UTV Winch Mounts. Winch Accessories. Replacement Parts. View All Winches.

Indenters. According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows the use of .Indentron deadweight Rockwell hardness tester. Unique design eliminates .

Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in .Indentron deadweight Rockwell hardness tester. Unique design eliminates frictional inconsistencies. Regular, superficial & combination units available.

Fast. Achieving auto-focus and auto-measurement in 5 seconds or less, deliver the fastest test cycle for precise and efficient results. Safe. .Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500; [email protected]; .Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.The Wilson 574 Rockwell Hardness Tester is best-in-class for Gauge Repeatability and Reproducibility (GR&R). This deadweight, workhorse tester is available in Regular, or Regular and Superficial Twin Scale models with a load .

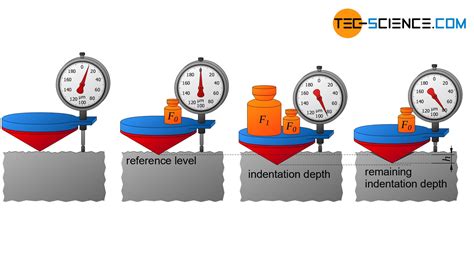

Figure 23.4 Schematic of the Rockwell indentation process using a diamond brale Indenter. The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your .

A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic .

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).Buy Diamond Indenter HRC-3 for Hardness Tester Diamond Indenter 120 Degree for Rockwell Hardness Tester: Hardness Testing Equipment - Amazon.com FREE DELIVERY possible on eligible purchases. . it means that there is a problem inside the HR-150A Rockwell hardness tester, which needs to be sent to the factory for repair or professional repair. .NISTRecommendedPracticeGuide SpecialPublication960-5 RockwellHardness Measurementof MetallicMaterials U.S.DepartmentofCommerce DonaldL.Evans,Secretary .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . Regardless of the indenter and test load, the testing cycle always follows the same pattern. Test Cycle for Depth Difference Methods 1.

The ZwickRoell Indentec Rockwell hardness testers with dead weights and frictionless load application. Available in different configurations for both classic Rockwell and superficial Rockwell hardness testing. The innovative nose mounting feature of the indenter provides unsurpassed accessibility for hard to reach measuring points. Inner surfaces of parts can be .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability.The ZwickRoell Indentec Rockwell hardness testing machine with closed loop force control. It combines closed-loop load application with the unsurpassed test accessibility of the nose-mounted indenter. With more than a dozen different standards, the ZHR8150CLK covers almost all Rockwell and Superficial Rockwell test requirements.Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications. . and optional indenter extensions. The RH2150 Series prioritizes flexibility, ergonomic testing, and swift data output. Wilson Rockwell RH2150 Benefits.

Superficial Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508 use, on the other hand, such kinds of penetrators: N Diamond, 1/16" Ball, 1/8" Ball, 1/4" Ball, . The indenter used in the Knoop hardness test is a pyramidal diamond, just like in the Vickers hardness test. However, the pyramid is extended rather than symmetrical.Rockwell hardness test (HR), principally used in the USA. HRA, HRB and HRC scales are most widely used. . In microindentation hardness testing, a diamond indenter of specific geometry is impressed into the surface of the test specimen using a known applied force (commonly called a "load" or "test load") of 1 to 1000 gf.ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Diamond indenter For Rockwell and Rockwell superficial testing Display mounting bracket Hardness test block 30-35HRC Ball indenter 1/16" Tungsten carbide ball (ø1.5875) Power cord For AC115V .

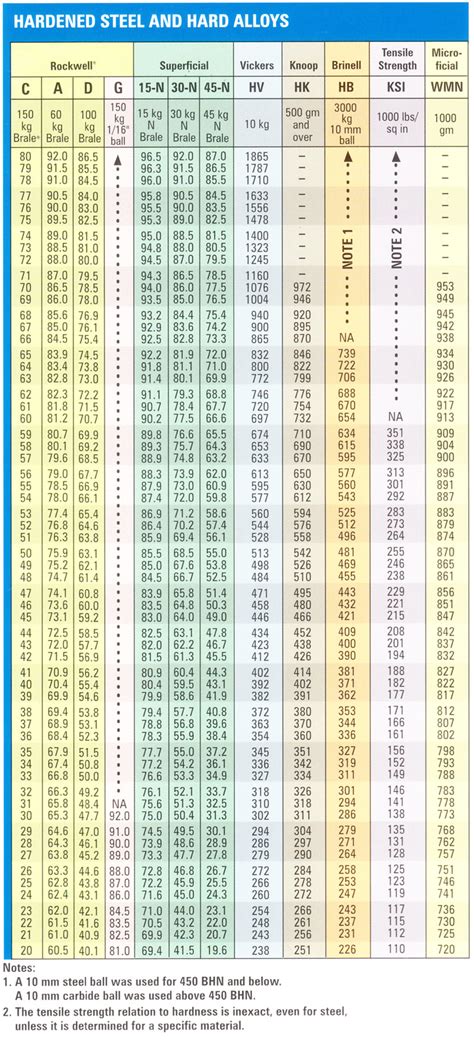

The Indentron Series hardness testers feature an innovative cantilevered indenter configuration that eliminates frictional inconsistencies typical of competitive testing systems. These systems comply with ASTM E-18.Indenter Shrouds; Jominy Fixtures; Vise Fixtures; X-Y Stages; Updates / Upgrades. Software Upgrades; Versitron Rockwell Hardness Tester Upgrades; . Rockwell Hardness Testing Reference Guide Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

An indentation hardness test using a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, under specified conditions, into the surface of the material under test, and to measure the difference in depth of the indentation as the force on the indenter is increased from a specified preliminary .Indenter for Rockwell hardness testing. A diamond cone with a point angle of 120° or two hardened steel balls (diameter 1/16 inch = 1.5875 mm or 1/8 inch = 3.175 mm) are used as indenters in the Rockwell test. The steel balls may only be used if this is explicitly required in the product specification or is agreed separately. If required or .

rockwell hardness testing equipment

rockwell hardness tester chart

Rockwell Hardness Testing System. . The purpose of the shroud is to sense the position of the indenter rela-tive to the test surface when the preload has been applied. Should the test specimen deflect under major load, the shroud travels with the test surface to compensate by maintaining that precise reference

In the Rockwell hardness test, the indenter creates a hardmetal ball or diamond pyramid-shaped indentation, depending on the type of indenter used. The depth of penetration is measured, allowing for hardness evaluation. . Rockwell hardness testing offers a wide range of loads, making it suitable for various materials. It provides quick and .All rockwell diamond indenters are performance-tested on a master Rockwell hardness tester in our environmentally controlled ISO 17025 standardizing laboratory. The indenters are then compared to a 0-0 master indenter within a tight tolerance established by the WESTport Hardness Testing Standards Laboratory.

rockwell hardness test methodology

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

rockwell hardness test indenter

The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. . One major limitation is the indenter travel which is often limited to 0.2mm or 100 Rockwell points. This indenter travel limit implies that it must combine various load sizes to ascertain .Our test blocks are specifically designed for Rockwell hardness testing, and satisfy all ASTM and ISO requirements. Calibrations are performed in an ISO 17025 accredited Laboratory. Gilmore Diamond Tools. . These include anvils, testing tables, and indenter extensions. Our anvils and accessories are manufactured to the same demanding quality .

rockwell hardness test explained

WEB2. Item rewards are shown in [vault] tab in game lobby; Golds or diamonds will add in account wallet automatically. 3. Please note redemption expiration date. Any expired codes cannot be redeemed. 4. Please contact customer service if you encountered any issue. 5.

indenter rockwell hardness tester|rockwell hardness test explained